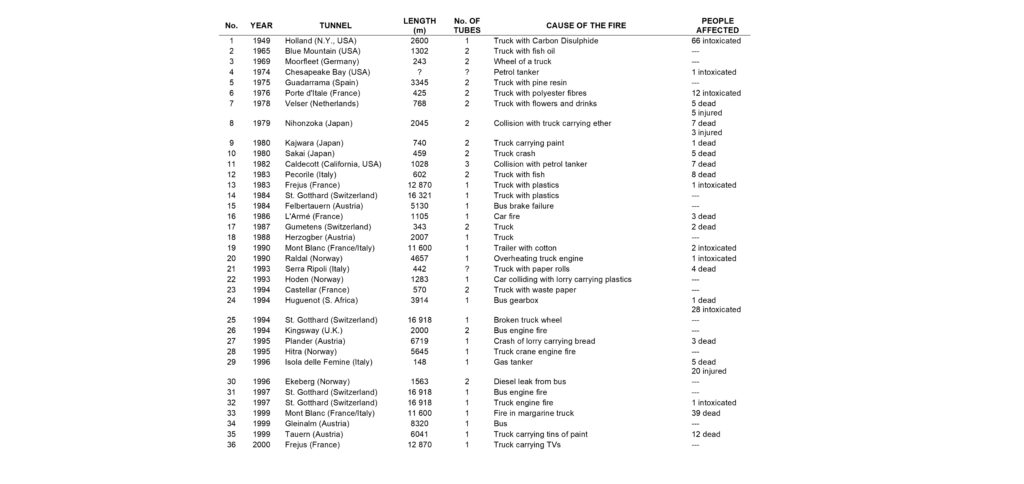

Towards the end of the 20th century there were several accidents involving fires in European tunnels, with a high number of fatalities. In particular, 39 fatalities occurred in the Montblanc Tunnel (France/Italy) and 12 in the Tauern Tunnel (Austria). The following table shows relevant information on fires in road tunnels in the second half of the 20th century.

Although tunnel sections of a road have a lower accident rate than open-air roads (1/3 for two-way tunnels compared to open-air roads, and 1/6 for one-way tunnels compared to open-air roads), the consequences of a fire in a tunnel are significantly worse in terms of casualties (injuries and/or deaths). Given the terrible consequences of these fires, social awareness was severely shaken, resulting in the development of new tunnel safety regulations by the relevant authorities.

The following table shows, by way of example, several of the most significant road tunnel safety regulations in force in 2023, with their geographical scope of application:

The regulations cited set out the criteria for the provision of the corresponding safety equipment for tunnels, depending on their characteristics; e.g. for RD 635/2006 applicable in Spain, depending on the type of tunnel (one-way or two-way, urban or interurban), its length and the level of traffic it accommodates.

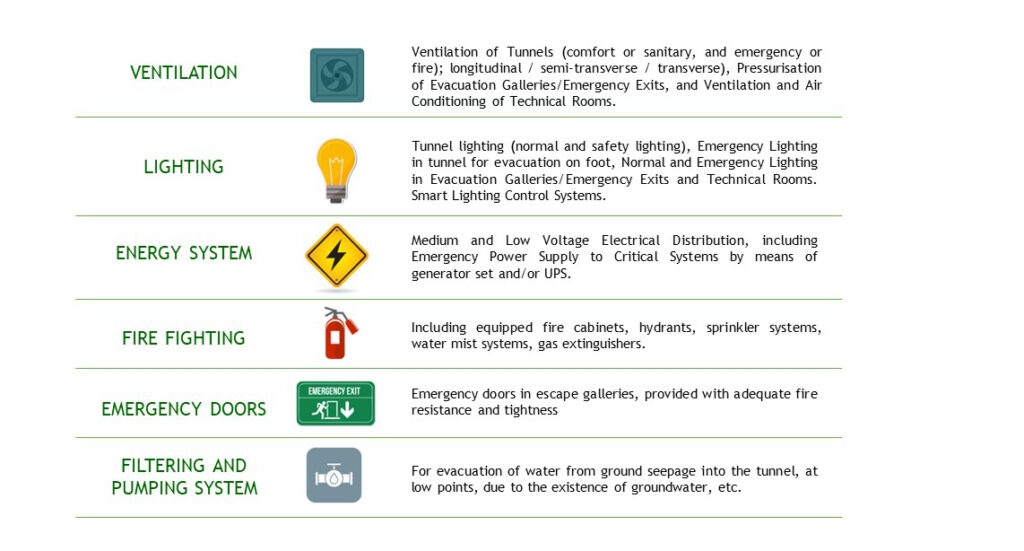

Electromechanical systems are fundamental part of the safety installations/equipment of a tunnel, including:

The life cycle of a tunnel and its safety and control systems goes through several stages, from definition and design, through supply, installation, testing and commissioning, operation and maintenance, to final decommissioning. Each of them is crucial to ensure the safety, effectiveness and efficiency of the tunnel. Electromechanical systems, as well as all other tunnel safety systems, must be designed from a holistic perspective, taking into account their entire life cycle.

The maintenance and operation of the tunnel safety, control and automation installations must be carried out by means of a integrated platform for the management of the tunnel (or tunnels), from which all the systems are controlled and monitored, guaranteeing maximum safety and operability in daily management and in emergency situations. This is the SCADA (Supervisory Control and Data Acquisition).

All security systems are integrated and controlled by SCADA. There are two different situations in this regard:

- In the case of a new tunnel, with new safety systems, the systems integration may be more or less complex, but the tunnel is closed to traffic in order to carry out all the necessary actions prior to commissioning.

- When it comes to work on an existing tunnel, where the intention is to make improvements to existing systems, or to provide it with certain new safety systems, there are two other variables to be taken into account:

- Generally, the tunnel has to be kept open to traffic, at least partially, which entails greater complexity in the planning of the works, establishing traffic detours via alternative routes, etc.

- For the same reason, safety systems must be kept operational, which also means that existing systems are kept in operation simultaneously with the implementation of the upgrades, and that at a certain point the old systems are switched off and the new ones are brought online (e.g. in the replacement of tunnel lighting with VSAP by new LED floodlights). This adds greater complexity to the SCADA integration work of the systems/migration to the new systems.

SIDERA ITS&TUNNELS is the SCADA or advanced smart control and management platform developed by SICE, which adapts to the needs of each client and project. This platform receives real-time information on the operation of the systems and equipment installed in the tunnel, detecting possible problems and offering corrective and preventive measures in a timely manner. SICE also has an integrated management solution for multi-tunnel environments, which includes the capacity to integrate the operating systems and the capacity to monitor all their components, allowing the systems of multiple tunnels to be controlled centrally, guaranteeing maximum safety and operability.

Electromechanical systems must have the highest levels of reliability, availability, maintainability and safety. Likewise, efforts are now being made to install state-of-the-art technology to minimise the tunnel’s energy consumption, reducing the carbon footprint and aiming for zero emissions. For example:

- Projectors with LED technology are used, which are much more energy-efficient than traditional systems (VSAP, metal halide, fluorescent, etc.)

- Smart lighting control systems are used, depending on outdoor brightness, weather conditions, traffic level and speed, etc. In combination with LED technology, this allows for greater energy savings.

- Variable frequency drives are used for the jet fans, resulting in considerable energy savings, and better operability in terms of handling fumes in the event of a fire in the tunnel.